Form Diameter Spline

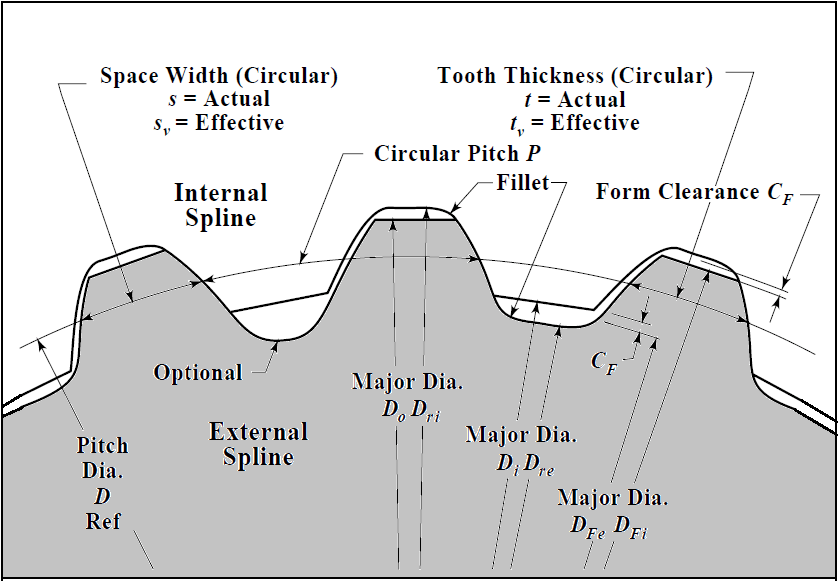

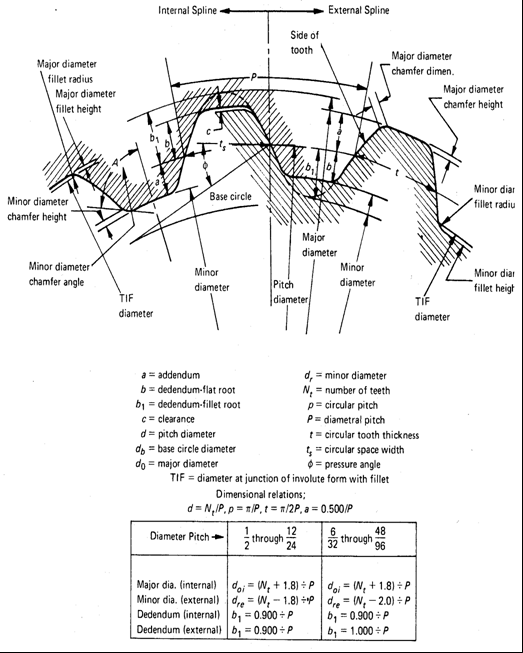

Form Diameter Spline - Involute splines have maximum strength at the. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. The internal spline is held to basic dimensions and the external spline is varied to control the fit. For example, iso h7 (the outside diameter of the. 300 spline flat root major dia. To control tolerances , the minimum efffective space width and the minimum major. Internal splines are formed by broaching or by a gear shaper. The tolerance of the major diameter of the internal spline should be selected as a transition fit;

The tolerance of the major diameter of the internal spline should be selected as a transition fit; 300 spline flat root major dia. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. The internal spline is held to basic dimensions and the external spline is varied to control the fit. Internal splines are formed by broaching or by a gear shaper. Involute splines have maximum strength at the. To control tolerances , the minimum efffective space width and the minimum major. For example, iso h7 (the outside diameter of the.

Involute splines have maximum strength at the. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. The tolerance of the major diameter of the internal spline should be selected as a transition fit; For example, iso h7 (the outside diameter of the. Internal splines are formed by broaching or by a gear shaper. To control tolerances , the minimum efffective space width and the minimum major. The internal spline is held to basic dimensions and the external spline is varied to control the fit. 300 spline flat root major dia.

Spline shaft 16/3223T

300 spline flat root major dia. The internal spline is held to basic dimensions and the external spline is varied to control the fit. Involute splines have maximum strength at the. Internal splines are formed by broaching or by a gear shaper. The tolerance of the major diameter of the internal spline should be selected as a transition fit;

HEXAGON Info letter no. 65

For example, iso h7 (the outside diameter of the. 300 spline flat root major dia. Involute splines have maximum strength at the. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. The tolerance of the major diameter of the internal spline should be selected as a transition fit;

Spline Gauges Kanak Machine Tools

Internal splines are formed by broaching or by a gear shaper. 300 spline flat root major dia. Involute splines have maximum strength at the. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. To control tolerances , the minimum efffective space width and the minimum major.

what is FORM DIAMETER IN A GEAR !!!!!! YouTube

To control tolerances , the minimum efffective space width and the minimum major. 300 spline flat root major dia. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. For example, iso h7 (the outside diameter of the. The tolerance of the major diameter of the internal spline should be selected.

Spline Design Photos All

Involute splines have maximum strength at the. The internal spline is held to basic dimensions and the external spline is varied to control the fit. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. Internal splines are formed by broaching or by a gear shaper. To control tolerances , the.

SPLINE CLARIFICATION PLEASE Gear & Pulley engineering EngTips

The internal spline is held to basic dimensions and the external spline is varied to control the fit. Internal splines are formed by broaching or by a gear shaper. Involute splines have maximum strength at the. The tolerance of the major diameter of the internal spline should be selected as a transition fit; 300 spline flat root major dia.

Harness the Optimum Torque Transmission With an InDepth Look on Gear

300 spline flat root major dia. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. To control tolerances , the minimum efffective space width and the minimum major. The tolerance of the major diameter of the internal spline should be selected as a transition fit; The internal spline is held.

Machinery splines

The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. The tolerance of the major diameter of the internal spline should be selected as a transition fit; 300 spline flat root major dia. Internal splines are formed by broaching or by a gear shaper. For example, iso h7 (the outside diameter.

identifying an involute spline Gear & Pulley engineering EngTips

Internal splines are formed by broaching or by a gear shaper. Involute splines have maximum strength at the. 300 spline flat root major dia. The internal spline is held to basic dimensions and the external spline is varied to control the fit. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute.

How To Draw Involute Gear alter playground

300 spline flat root major dia. Involute splines have maximum strength at the. The following are equations and engineering design calculator to determine critical design dimensions and features for an involute gear. The tolerance of the major diameter of the internal spline should be selected as a transition fit; Internal splines are formed by broaching or by a gear shaper.

To Control Tolerances , The Minimum Efffective Space Width And The Minimum Major.

The tolerance of the major diameter of the internal spline should be selected as a transition fit; Internal splines are formed by broaching or by a gear shaper. The internal spline is held to basic dimensions and the external spline is varied to control the fit. 300 spline flat root major dia.

The Following Are Equations And Engineering Design Calculator To Determine Critical Design Dimensions And Features For An Involute Gear.

For example, iso h7 (the outside diameter of the. Involute splines have maximum strength at the.